Mon-Sat 9.00 AM - 6.00 PM

Mon-Sat 9.00 AM - 6.00 PM Mon-Sat 9.00 AM - 6.00 PM

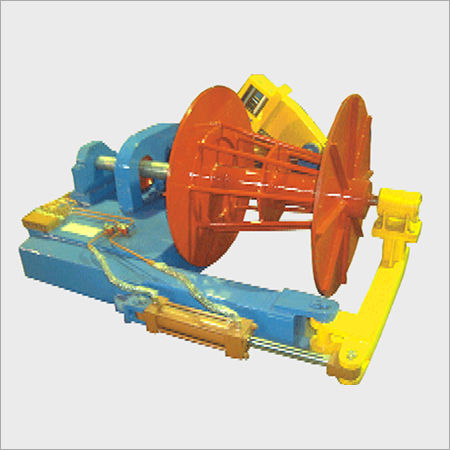

Mon-Sat 9.00 AM - 6.00 PMHydraulic Scrap Winders

Product Details:

- Control System Push Button Control

- Wheel Type Heavy Duty PU Wheels

- Motor Type Three Phase Induction Motor

- Handle Type Ergonomic

- Equipment Type Hydraulic Scrap Winder

- Rotation Type Hydraulic Powered

- Belt Type Steel

- Click to View more

Hydraulic Scrap Winders Price And Quantity

- 1500000.00 - 2000000.00 INR/Unit

- 1000000.0 INR/Unit

- 1 Unit

Hydraulic Scrap Winders Product Specifications

- Hydraulic Powered

- High Efficiency, Compact Design

- Hydraulic Scrap Winder

- Steel

- Easy Maintenance, Safety Interlocks

- Other

- Up to 2000 Kg Kilograms (kg)

- m/s

- Push Button Control

- 415 V Volt (v)

- Up to 6 meters Meter (m)

- 2000 Kg Kilograms (kg)

- 2-5 kW Kilowatt (kW)

- New

- Heavy Duty PU Wheels

- Ergonomic

- Three Phase Induction Motor

Hydraulic Scrap Winders Trade Information

- 1 Unit Per Month

- 2 Months

Product Description

Run by single phase power source, this Hydraulic Scrap Winder deserves praise for its long working life and high output. Offered hydraulic power controlled system can bear 30 ton to 60 ton maximum load. This system can handle 25 mm wide and 6 mm thick load without any hindrance. Managed by hydraulic motor, this industrial equipment has hydraulically controlled bundle ejection system and automatic variable speed controller. Long working life, low maintenance design, high strength and ease of handling are some of the key aspects of this Hydraulic Scrap Winder.

Product details

| Body Material | Mild Steel |

| Machine Power | Hydraulic |

| Scrap Winders Capable of Handling Thickness | 6 mm |

| Scrap Winders Capable of Handling Width | 25 mm |

| Max Force Or Load | 30-60 ton |

| Phase | Single Phase |

| Brand | Pragya |

Customizable Solutions for Scrap Winding

Hydraulic Scrap Winders are tailored to suit the specific needs of steel and aluminum plant operators. Drum diameter and belt length can be adjusted to match unique scrap handling requirements, supported by both standard and fully customized designs. Quality materials like mild steel and stainless steel ensure both durability and superior performance.

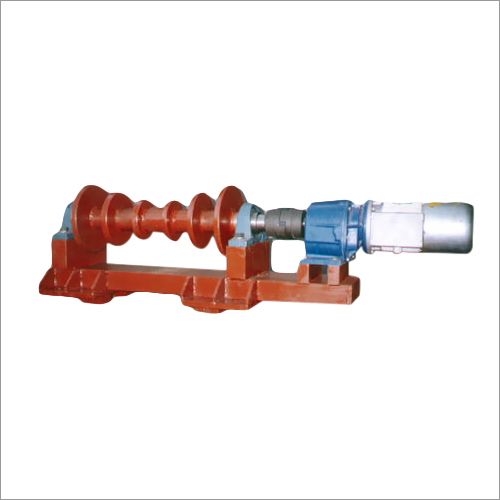

Reliable and Efficient Operation

Equipped with a powerful three-phase induction motor and hydraulic-powered rotation, these winders combine high efficiency with low noise and energy consumption (25 kW). Easy push-button controls, adjustable speed features, and safety interlocks make operation user-friendly and secure during heavy-duty applications.

Heavy-Duty Construction and Easy Maintenance

Designed for continuous industrial use, the winders feature paint or powder-coated finishes for extra durability and corrosion resistance. The ergonomic handle and heavy-duty PU wheels provide hassle-free mobility. Maintenance is straightforward thanks to robust engineering and thoughtfully integrated access points.

FAQs of Hydraulic Scrap Winders:

Q: How can the Hydraulic Scrap Winder be customized for different plant requirements?

A: The drum diameter and belt length of the Hydraulic Scrap Winder can be fully customized to meet specific operational needs, allowing seamless integration into various layouts in steel or aluminum plants.Q: What is the primary application of this Hydraulic Scrap Winder?

A: This equipment is primarily used in steel and aluminum plants for efficient winding, handling, and removal of scrap materials during production processes.Q: When is it necessary to opt for a heavy-duty winder like this model?

A: A heavy-duty Hydraulic Scrap Winder becomes essential when processing large volumes of scrap or handling materials with substantial weight, up to 2000 kg, ensuring uninterrupted and safe operation in demanding environments.Q: Where can this Hydraulic Scrap Winder be installed?

A: It is suitable for installation in a variety of industrial settings, particularly steel and aluminum plants, thanks to its compact design and adjustable features that allow it to fit seamlessly into existing workflows.Q: What is the process for operating the machine and ensuring safety?

A: Operation is semi-automatic, utilizing a push-button control system for hydraulic-powered rotation. Safety is enhanced through built-in safety interlocks and ergonomic handles for safe manual handling during setup or relocation.Q: What benefits do users gain from this winders compact design and efficiency?

A: The compact design maximizes usable floor space, while high efficiency results in faster scrap processing, reduced energy consumption, and lower noise levels, contributing to an improved working environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese