Mon-Sat 9.00 AM - 6.00 PM

Mon-Sat 9.00 AM - 6.00 PM Mon-Sat 9.00 AM - 6.00 PM

Mon-Sat 9.00 AM - 6.00 PMHydraulic Belt Wrapper

Product Details:

- Belt Type Polyester Reinforced Rubber

- Rotation Type 360 Degree Rotational Function

- Control System Semi Automatic

- Equipment Type Hydraulic Belt Wrapper

- Lifting Speed 8 m/min m/m

- Motor Type Hydraulic Driven Motor

- Handle Type Ergonomic Handle

- Click to View more

Hydraulic Belt Wrapper Price And Quantity

- 1000000.0 INR/Unit

- 1500000.00 - 2000000.00 INR/Unit

- 1 Unit

Hydraulic Belt Wrapper Product Specifications

- New

- 1800 mm Millimeter (mm)

- Up to 2 Tons Tonne

- Customizable, Standard 5 m Meter (m)

- 360 Degree Rotational Function

- Polyester Reinforced Rubber

- 220V - 240V Volt (v)

- Other

- 2000 kg Kilograms (kg)

- Energy Saving, Enhanced Safety

- High Efficiency, Low Noise

- Not Included

- Ergonomic Handle

- Hydraulic Driven Motor

- 8 m/min m/m

- 2.2 kW Kilowatt (kW)

- Hydraulic Belt Wrapper

- Semi Automatic

Hydraulic Belt Wrapper Trade Information

- 1 Unit Per Month

- 2 Months

Product Description

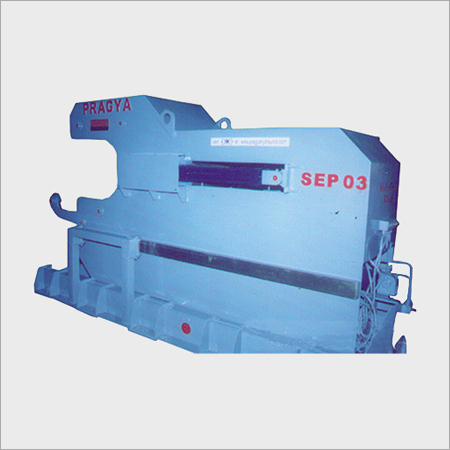

This heavy duty Hydraulic Belt Wrapper is suitable for wrapping of cold rolled and hot rolled coils having maximum 6 mm thickness and up to 1500 mm width. Operated by three phase power supply system, this hydraulic equipment has 2 MT to 35 MT production capacity range. Excellent load bearing capacity, easy to adjust keeper arms and hydraulically controlled pivot and lift are some of the key characteristics of this Hydraulic Belt Wrapper. Entire design of this machine can be custom made to suit specific production requirements.

Product details

| Equipment Can Handle Thickness | Up to 6.0 mm |

| Equipment Can Handle Width | Up to 1500 mm |

| Working Capacity | 2MT to 35 MT |

| Phase | 3 |

| Material | Mild Steel |

| Voltage | 420 V |

| Brand | Pragya |

| Usage/Application | Wrapping of CR and HR Coils |

Heavy-Duty Performance & Robust Construction

The hydraulic belt wrapper delivers outstanding strength and reliability thanks to its mild steel frame and high-quality powder coating. Designed for heavy-duty use, it accommodates up to 2 tons and can operate effectively within an ambient temperature of 5C to 45C. Whether in warehouses or manufacturing facilities, this robust construction assures durability and consistent operation under various conditions.

Advanced Semi-Automatic Control & Safety

With its user-friendly digital display control panel and semi-automatic operation, users can easily monitor and manage the wrapping process. Enhanced safety measures, including an emergency stop and overload protection, prioritize operator safety without compromising efficiency. Its moderate energy consumption (2.2 kW) and energy-saving features support both productivity and sustainability in industrial packaging applications.

Customizable & Highly Mobile Design

The wrapper is equipped with a polyester reinforced rubber belt available in customizable lengths, standard at 5 meters, to fit a variety of packaging needs. The ergonomic handle and heavy-duty swivel wheels, combined with a 360-degree rotational function, enable effortless handling and improved maneuverability. Adjustable rack capacity and robust lift capabilities make it versatile for diverse packaging scenarios.

FAQs of Hydraulic Belt Wrapper:

Q: How does the hydraulic belt wrapper operate and what is its control system?

A: The hydraulic belt wrapper operates on a semi-automatic mode, managed through a digital display control panel. This intuitive system allows users to monitor parameters and control wrapping functions with ease, ensuring efficient and safe packaging operations.Q: What types of materials and packaging applications is this wrapper best suited for?

A: Designed for heavy-duty applications, the wrapper is ideal for industrial packaging of pallets, machinery, or bulk goods. Its robust construction and customizable belt length make it suitable for a variety of load sizes, especially where up to 2 tons lifting is required.Q: Where can the hydraulic belt wrapper be installed and in what environments does it perform best?

A: This equipment is suitable for use in warehouses, manufacturing plants, and distribution centers. Functioning reliably within ambient temperatures from 5C to 45C, it is designed to withstand demanding industrial conditions without performance compromise.Q: What benefits does the hydraulic belt wrapper provide over manual or less automated systems?

A: Compared to manual or less automated systems, this wrapper offers higher efficiency (35 loads per hour), enhanced safety features like emergency stop and overload protection, energy savings, and significantly reduced noise levels (70 dB), ensuring both productivity and operator comfort.Q: What is involved in the set-up process for customizable belt lengths?

A: Customers can specify the desired belt length (standard 5 meters, customizable upon request) at the time of order. The manufacturer adjusts the installation accordingly to ensure the equipment meets unique packaging requirements without any operational compromise.Q: What maintenance is required for the hydraulic system and belt?

A: Regular inspection and timely replacement of ISO VG 32 hydraulic fluid are recommended to maintain optimal hydraulic function. Cleaning and routine checks of the polyester reinforced rubber belt will also help extend the life and efficiency of the equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese